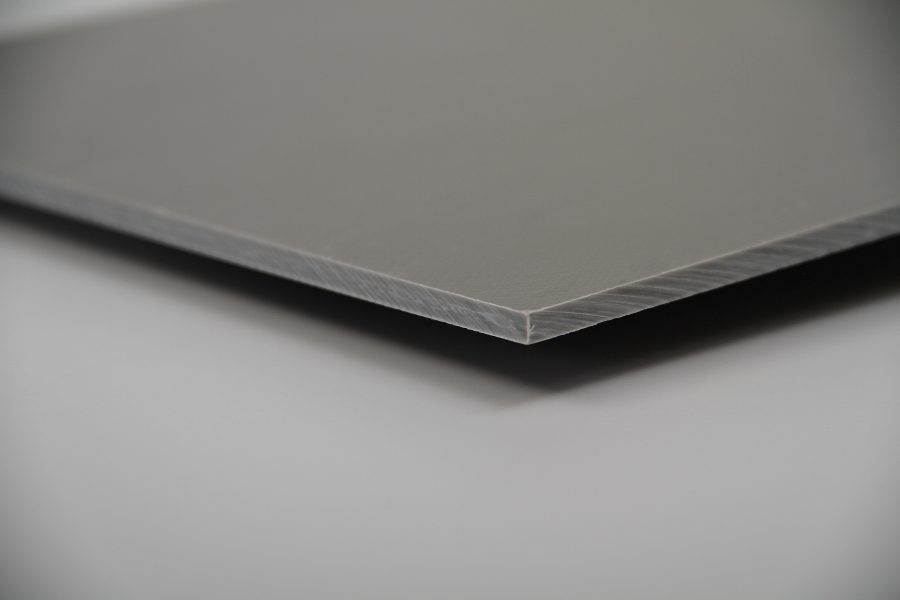

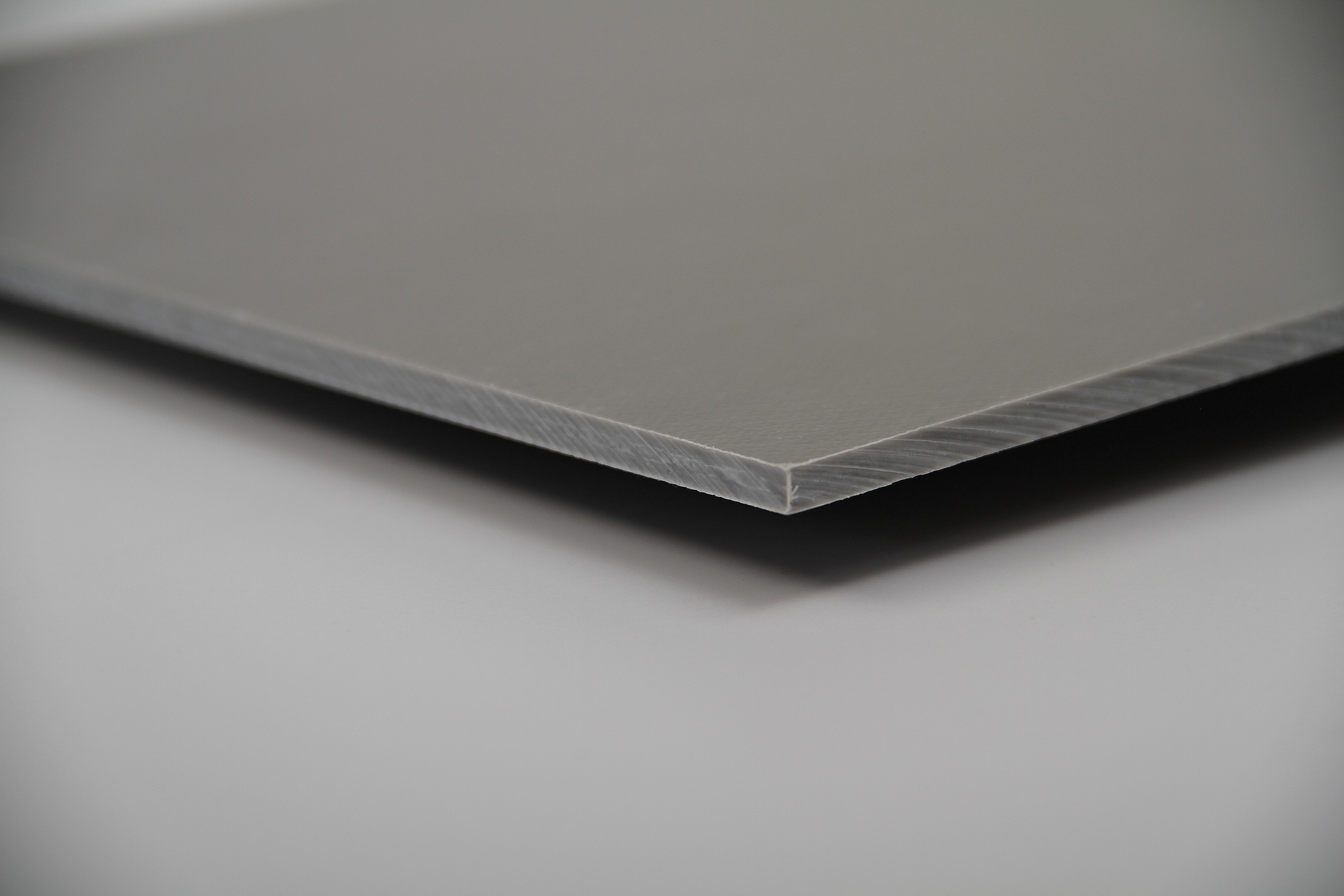

Kaisersesch. The CLASSEN Group, one of the leading international manufacturers of floor coverings, sees its CERAMIN material as an important building block for reducing the amount of plastic waste in the future. CERAMIN is based on the plastic polypropylene (PP), is 100% recyclable and contains no PVC and therefore no chlorine, stabilisers, phthalates or other plasticisers. Approximately 25 % of the finished product is post-consumer recycled material. So far, the material has been used, among other things, as a waterproof coreboard for non-PVC vinyl flooring from CLASSEN.

The flooring industry expects 920 million square metres of vinyl/design flooring to be produced worldwide in 2023 alone (source: BTH Heimtex 7-8/2019). Still 98 percent of these polymer floorings are based on PVC. The PVC formulations require modification with plasticisers to be suitable material for the manufacturing of flooring. Unfortunately, theses plasticisers migrate out of the flooring after installation and have been linked negative health effect on hormonal balances in humans. Thus, heavy metal stabilisers and certain plasticisers from before 2014 make it impossible to recycle and reuse soft PVC. These quantities end up in waste disposal or in special incineration plants, in which a lot of carcinogenic dioxins are released as degradation products of chlorine during incineration.

The OECD (Organisation for Economic Co-operation and Development) confirmed in a study at the end of February 2022 (https://www.oecd-ilibrary.org/environment/global-plastics-outlook_de747aef-en) that only little plastic is recycled. According to the study, global plastic production almost doubled between 2000 and 2019, but only nine per cent of it was recycled in 2019. According to the OECD, 19 per cent of the waste is incinerated, almost 50 per cent ends up in landfills, and the remaining share of around 22 per cent is disposed of illegally. A large proportion eventually ends up in the sea from land as microplastics, leading to the death of marine animals, restricting their locomotion and growth, reducing food intake or reproductive capacity and altering animal behaviour. It also accumulates in the marine food chain (source: study by WWF (World Wildlife Fund) and the Alfred Wegener Institute (AWI), February 2022, https://wwf.panda.org/wwf_news/press_releases/?4959466/Ocean-plastic-pollution-to-quadruple-by-2050-pushing-more-areas-to-exceed-ecologically-dangerous-threshold-of-microplastic-concentration)

CERAMIN is produced with recycled materials and 100 % recyclable

CERAMIN was developed in such a way that it is fully recyclable and does not have to be landfilled. Felix Hüllenkremer, Head of Research and Development at CLASSEN: “In line with our motto ‘Floors For A Better Tomorrow’, with CERAMIN we have found a solution for not foregoing the advantages of plastic and at the same time fully integrating it into the circular economy. With our CERAMIN-based floor coverings, we offer a prime example of how industry can develop sustainable innovations that do not burden future generations. We also invite other manufacturers to learn about and use CERAMIN as the material of the future for flooring and other plastic products.”

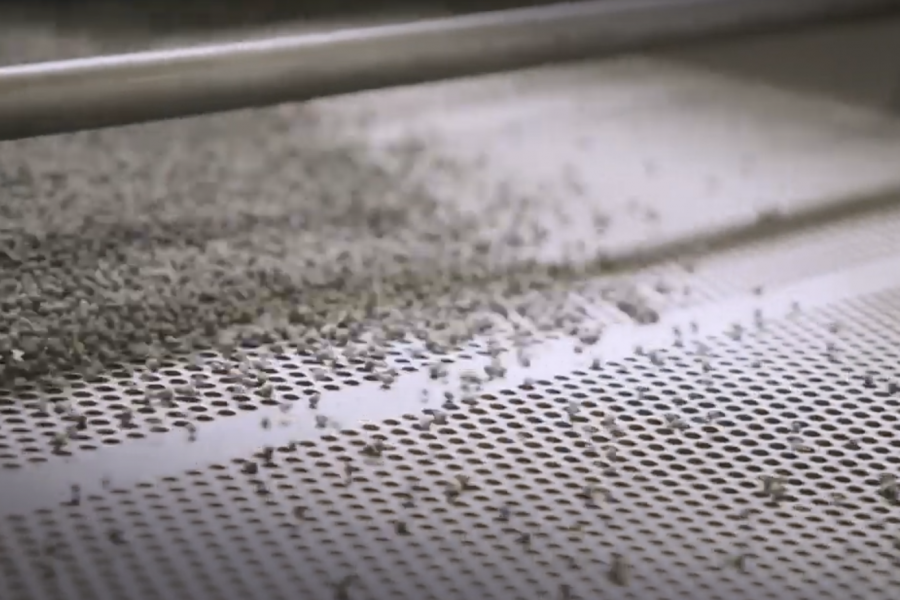

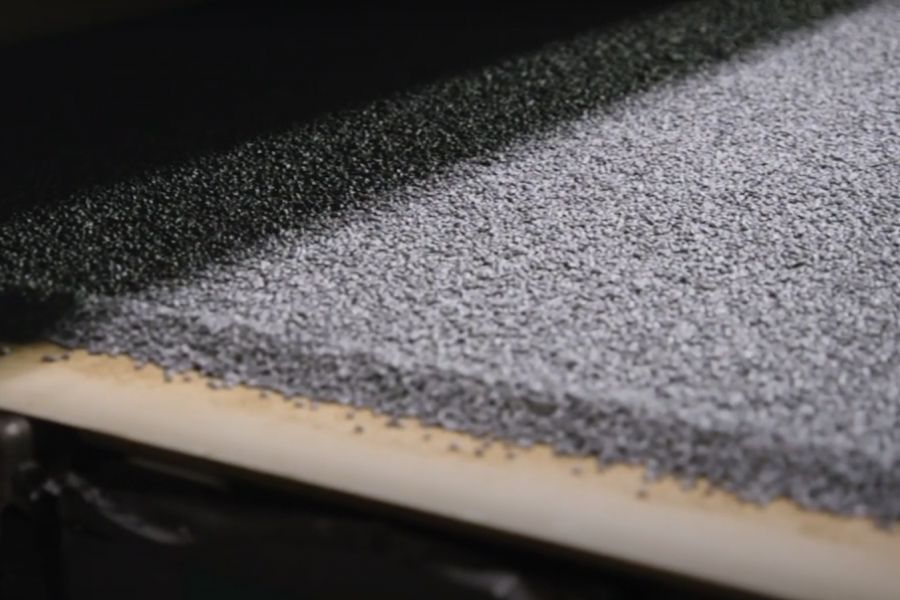

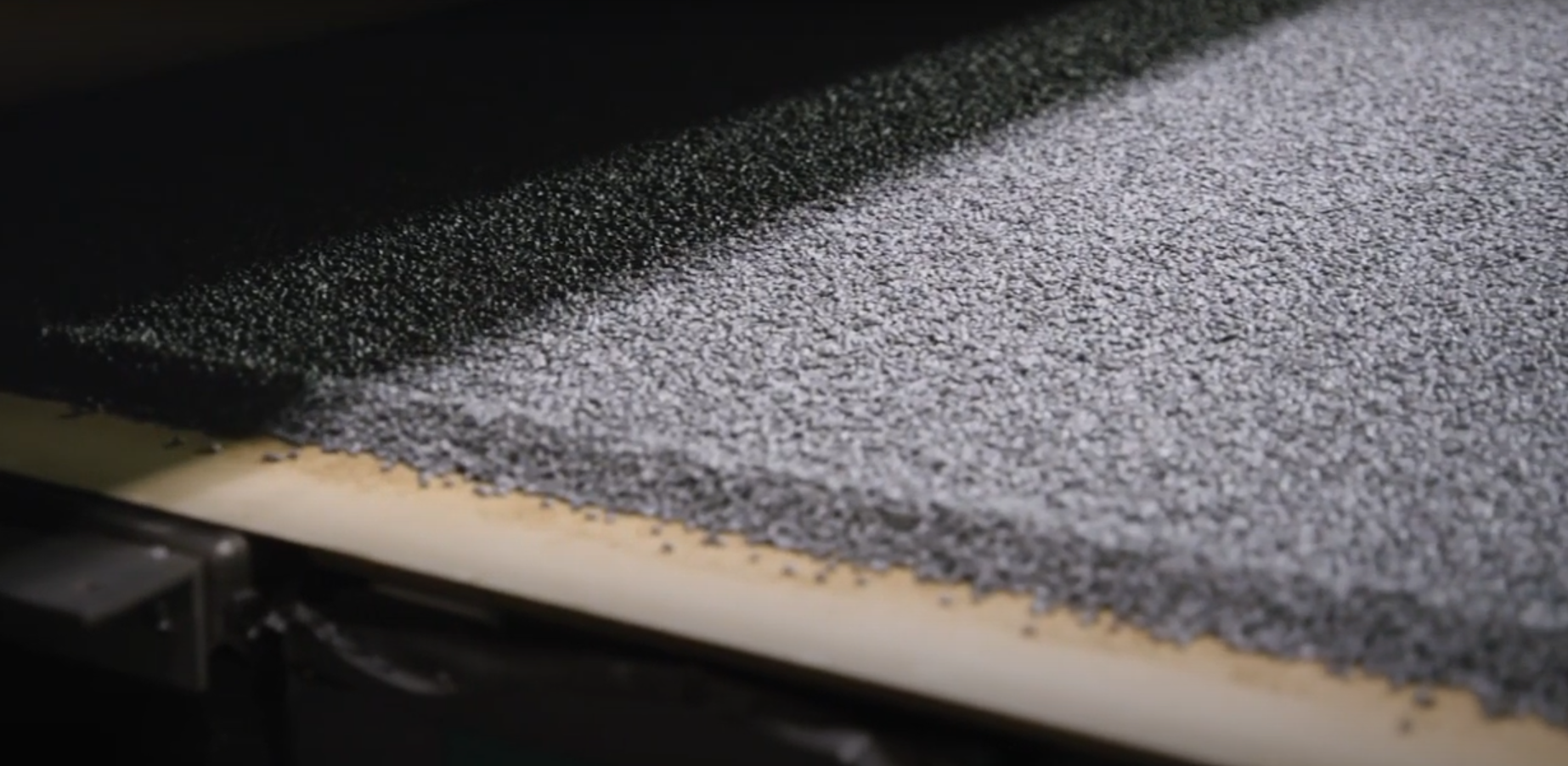

CERAMIN consists of 60 % natural mineral filler, 39 % polypropylene (PP) based polymers and one percent environmentally and health friendly additives. The material fulfils the requirements of the EU Strategy of Plastics for optimal recyclability, durability, reusability and a production process that uses internal production scrap and external post consumer recycled content. CLASSEN is also a member of the EU’s Circular Plastic Alliance, which aims to use ten million tonnes of recycled in plastic products or packaging by 2025. CLASSEN currently uses 13,000 tonnes of recycled material per year. For the coming years, the production volume of CERAMIN is to be further increased, so that the amount of recycled material used will also increase.

The recycled material in CERAMIN include, for example, packaging from food packaging. By using them in CERAMIN, the recycled material is upcycled into a high-quality product with a long service life. CERAMIN is also recyclable after its life cycle. In addition to recycling in a new flooring product, this also means that the raw material can be reused outside the flooring industry. The independent plastics recycling network of plastship GmbH has tested CERAMIN for its recyclability and certifies it as highly recyclable.

CLASSEN is actively involved in the circular economy of plastic products worldwide and is continuously expanding cooperations with various partners. In Germany, CLASSEN has established a partnership with Hündgen Entsorgungs GmbH & Co. KG, an operator of sorting plants for recyclable materials, CLASSEN has founded the joint venture HC Plastics GmbH.

All CLASSEN CERAMIN products meet the requirements of the German government’s “Der Blaue Engel” environmental seal in accordance with the new RAL UZ 120 award guidelines, as well as the regional environmental seals A+, Green Guard and the eco Institute.

You can find more about products with CERAMIN: here.